Copyright © 2025 PyroCCS | All rights reserved

By using this website you agree to our Privacy Policy and understand the information presented has informational character.

We have developed industrial biochar projects using various technologies and pyrolysis plants from across the world.

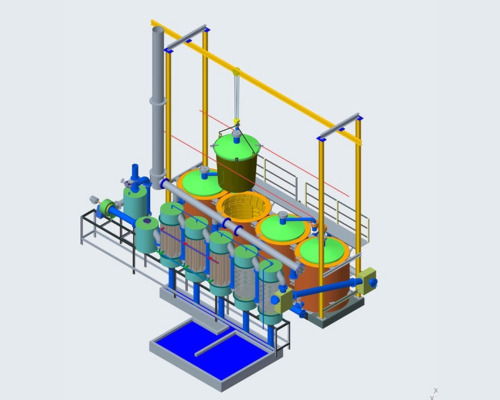

Our low-cost, robust semicontinuous batch technology fully powered by solar energy for deployment in rural, decentralised settings. The system is optimised for the extraction of biooils as byproducts (wood vinegar and wood tar).

Rapid setup times of less than five months allow deployment at large scale.

The SCB technology works extremely well in arid climates with more coarse feedstock like logs, branches, bamboo or briquettes.

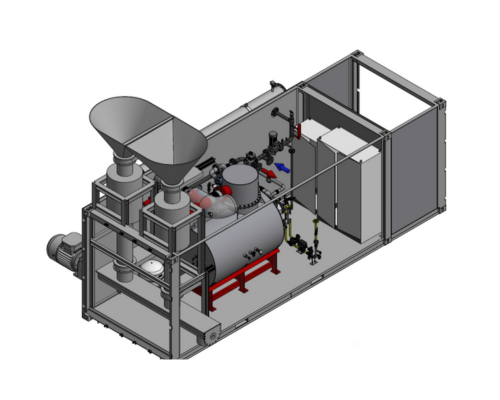

Our containerised continuous XS technology is ideal for decentralised deployment with a small footprint.

The robust Gravity Reactor technology requires a minimum amount of maintenance and cleaning. Extremely high pyrolysis temperatures create biochar with a maximum yield of organic carbon.

The XS technology works well in all climatic zones. The system has a lot of waste heat that can be used to dry biomass even in wet conditions. The system works with finer biomass fractions like pellets, wood chips, nut shells etc.

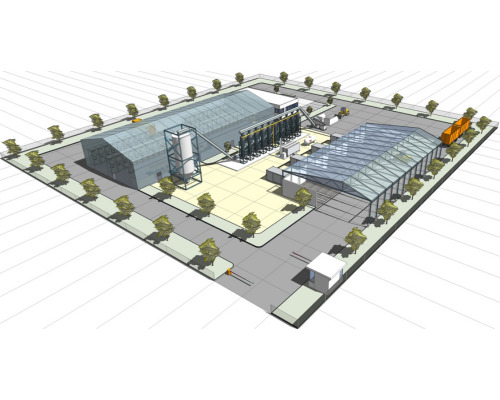

Our XL technology is the “big brother” of the XS technology.

It works with significantly larger biomass streams e.g. from industrial food processing. It has enough waste heat to not only dry the biomass but also provide further excess heat for industrial boilers etc.

The system is highly modular and can accommodate future expansion.

| SCB | XS | XL | |

|---|---|---|---|

| Biomass Input | up to 3,500 tons per year | up to 4,800 tons per year | up to 25,000 tons per year |

| Biochar Output | up to 1,100 tons per year | up to 1,800 per year | up to 8,000 tons per year |

| Carbon Credits | up to 2,200 per year | up to 4,000 per year | up to 18,000 per year |

| Reactor Type | Semi Continuous Batch System | Continuous Gravity Reactor System | Continuous Gravity Reactor System |

| Feedstock | Coarse biomass with maximum 15% moisture e.g. logs, branches, bamboo, wood cuttings, briquettes etc. | Finer biomass e.g. pellets (from various biomasses like straw, coffee husk, saw dust, EFB), wood chips, nut shells, corn cobs etc. | Finer biomass e.g. pellets (from various biomasses like straw, coffee husk, saw dust, EFB), wood chips, nut shells, corn cobs etc. |

| Pyrolysis Temperatures | up to 550 degrees celsius | up to 900 degrees celsius | up to 900 degrees celsius |

| Byproducts | Yes, wood tar and wood vinegar | No | No |

| Waste Heat for Drying | No | Yes, separate dryer required | Yes |

| Pyrolysis Gas Recycling | Yes | Yes | Yes |

| Operational Hours | 24/7, 330 days per year | 24/7, 320 days per year | 24/7, 320 days per year |

| Recommended Geographies | Arid, dry climate or where storage and drying of large amounts of biomass is possible | All | All |